About us

With 85 years of experience in hot forging, threading/thread rolling, machining, metal bending and hot dip galvanization Bayonet puts its expertise available to its customer to meet all their needs in fasteners and anchorage solutions.

Choosing Bayonet means opting for a partner with a high-performance team and a constantly modernized production tool.

From co-design to production in small, medium and large series, Bayonet assists you during all your requests for special and standard bolts, studs, tie rods, anchors, threaded rods etc.

History

The story of Bayonet begins in the village of Thilay located in the Ardennes.

The AVRIL’s family purchases the society.

In order to expand Bayonet is relocated: 3 Rue du Baquet, still in Thilay.

Investment in our first Rolling Machines.

The subsidiary AMS (Ardennes’ Metallurgic Society) is created and specializes in hot dip galvanizing for threaded parts.

The factory grows: The workshop space is doubled and brand new administration offices are created.

A roller is acquired to expand the products range to maximum 160 millimeters in diameter.

The CNC Turnings arrive. There’s a first quality investigation based on ISO 9002. A quality management also takes place.

Gas furnaces are replaced by induction heaters.

Bayonet becomes the main shareholder in the subsidiary SMA.

Expansion of premises to 1500m2.

High-capacity CNC lathe (Max length 3200mm) CMZ.

Installation of an Automatic carrier and loader CNC lathe

Company capabilities

Hot Forging

- 5 forging presses from 80 to 250 T

- 4 mechanic presses from 15 to 100 T

- 1 hydraulic presse 60T

Threading/Thread Rolling

- 8 Thread rolling machines M8 to M160 (Cold forming)

- 6 Threading machines

Machining

- 6 Computer Numerical Control Lathe (4 axis)

- 1 traditional lathe

- 1 grinding machine

Monitoring Tools

- Hardness measurements

- Profile projector

- Ring and Plug screw thread gages

Steel Park

- 1 overhead crane 2x 3.2T

- 2 automatic saws : cut up to ø330

- 3 shears : cut up to ø50

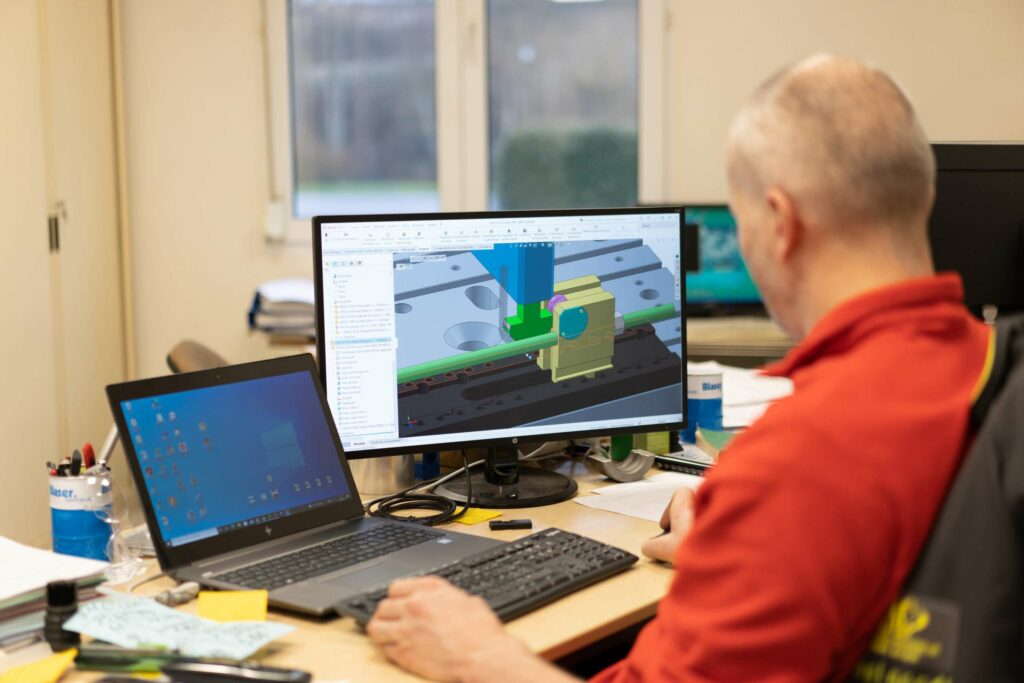

Planning and Design

A technical inquiry or a specific need, our research department can assist you in the design of your parts while taking into account our manufacturing possibilities.

Quality – Safety – Environment (QSE)

Experts in special and standard bolts, Bayonet manufactures all types of assembly bolts, anchoring bolts and fasteners.

The concerned sectors are varied: Energy, Transportation, Construction, Railway etc

Bayonet has put Quality Safety and Environment among its priority objectives since 1990.

These guidelines allow us to continuously improve our performance and thus obtain lasting satisfaction from our customers.

To carry out this quality policy, we want to focus on the following areas for improvement:

Improve the quality of services

Develop our production capacity

Restructure the general organization of the company

This goal can only be achieved by :

The complete and flawless adherence of staff and our suppliers

Independence of employees towards performance

Implementation and proposals of staff and supplier’s actions aimed at improving the various processes

I have appointed a Quality Manager to represent me on all quality matters. I give him full authority to :

Ensure that the quality management system is implemented and maintained

Remain aware of operations and any possible improvements

Encourage at all levels, awareness of customer requirements

I seek the commitment of all and I am convinced that we will continue our progress.

© 2025 BAYONET s.a. – All rights reserved – Legal Notice – Privacy Policy